Single stage single suction chemical centrifugal pump

Overview of single-stage single suction chemical centrifugal pump

Single stage single suction chemical centrifugal pumpProduct execution standards: GB5662-85 (obsolete), GB/T5662-2013 (current), ISO2858, GB/T5566-94 (obsolete), GB/T5566-2008 (current). Shenyang Shengong Fire Electrical Control Equipment Products: Fire Inspection Cabinet, Smoke Exhaust Fan Control Box/Fire Fan Control Box, Fire Control Cabinet, Fire Machinery Emergency Start Device.

The IH chemical pump is a single-stage single suction cantilever centrifugal pump, which is an energy-saving and updated product that replaces the F-type corrosion-resistant centrifugal pump.

Single stage single suction chemical centrifugal pumps are suitable for conveying corrosive liquids or non polluting media that do not contain suspended particles in industrial sectors such as petroleum, chemical, synthetic fiber, fertilizer, power station, metallurgy, food, and medicine. The temperature of the conveying medium is generally -20 ℃~105 ℃, and can reach 180 ℃ with special measures.

The speed of single-stage single suction chemical centrifugal pumps is divided into two types: 2900 and 1450 revolutions per minute. The performance is shown in the table below:

| Speed (r/min) | 2900 | 1450 |

| Maximum flow rate (m ³/h) | 240 | 400 |

| Maximum total head (m) | 125 | 55 |

Users can choose different materials for the main components of the pump's overcurrent section based on the corrosiveness level of the conveyed medium. The materials and codes of the main components of the overcurrent part of the single-stage single suction chemical centrifugal pump are as follows:

| material | ZG1Cr18Ni9 | ZG1Cr18Ni9Ti | ZG0Cr18Ni12Mo2Ti | ZG1Cr18Ni12Mo2Ti | ZG00Cr17Ni14Mo2 | ZG1Cr18Mn13Mo2CuN |

| code | 303 | 305 | 306 | 307 | 316L | 402 |

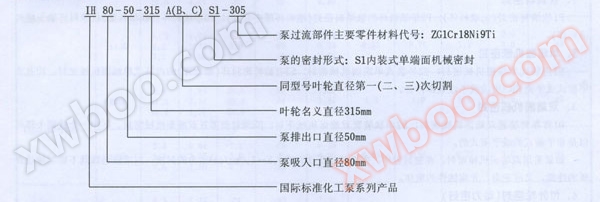

Model meaning

Meaning of single-stage single suction chemical centrifugal pump model

STRUCTURE DESCRIPTION

IH type chemical centrifugal pump system has a horizontal radial part and a rear opening door structure.

During maintenance, there is no need to disassemble the pipeline.

The pump body of a single-stage single suction chemical centrifugal pump is axial suction, radial discharge, and foot supported.

Lubricate the bearings with clean No. 22 mechanical oil. Before the pump starts running, lubricating oil should be added to the suspension to a position about 2 millimeters above the centerline of the oil gauge.

Large diameter impellers use back blades to balance axial forces.

An extended coupling is used to connect the pump to the prime mover.

Shaft seals include soft packing seals and single end and double end mechanical seals.

The rotation direction of the pump is clockwise when viewed from the prime mover end.